A & S McKay SHEET METAL FABRICATIONS

Leaders in precision sheet metal fabrication.

CONTACT US

For more information on any of our professional services or to get a quote for a project, contact our friendly team today.

Facilities

Skills

We employ time-served City & Guilds sheet metal workers. We have the skill and experience to weld all types of materials in all situations including:

- Welded stainless steel support

- Aluminium welding

- TIG welding

- MIG welding

- Electric arc welding

- Gas welding

- Brazing

- Soldering & silver soldering

We work to tolerances specified on the supplied drawings and to the appropriate British Standards.

Equipment & Capacities

- 20 tonne crane

- Two 6 tonne cranes

- 3m x 8mm Guillotine

- 2.5m x 6mm Guillotine

- 3m x 8mm Press brake

- 2.5m x 3mm Hydroform folder

- 2m Press brake

- 1m Press brake

- 2m x 6mm x 200mm diameter rollers

- Plasma cutter

- Laser cutter

- Oxy & acetylene

- Bandsaw

- Kingsland punch & cropper

- Various welding equipment: Electric arc, MIG & TIG

Design & Manufacture

As well as the design, manufacture and installation of steel fabricated products, we also provide various associated services. Most of these, punching, forming etc, make use of our excellent sheet metal work machines but we also provide various repair services.

Primarily this is the repair of aluminium and cast steel car and bike parts, but also includes specialist welding of ships hulls. Customers can give us their drawings, however when required we can produce our own.

Sometimes customers present us with an idea. We then work with them to develop the idea into a finished design that we can then manufacture. Designs generally fall into three categories:

Ingenius

These are the 'how can we make this do that?' type of problem. Typically, this includes such things as designing safety guards that don't obstruct production.

Aesthetic

These projects are invariably one-offs where the customer wants something contemporary, stylish and striking to look at. Examples we have made include the globe we built for St. David's Park and items such as a stainless-steel bed for a loft apartment.

Engineering

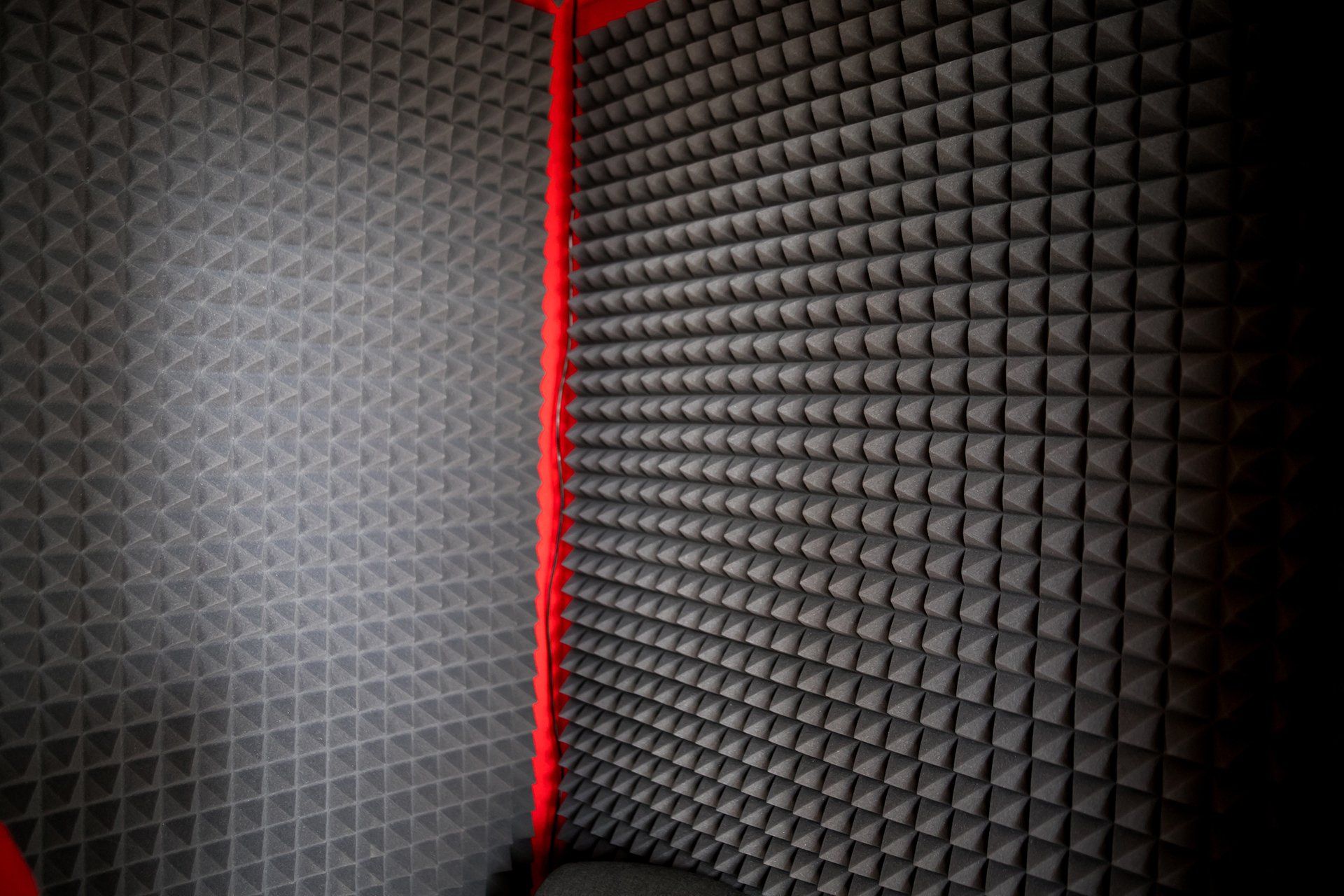

These are projects which might usually require architects and/or structural engineers such as large platforms or fire escapes. Typically, it might be the design of noise reduction acoustic booths.

If It’s Made from Metal

We Can Do It

We provide full service sheet metal fabrication from design, to manufacture, to assembly and installation. We have a thorough understanding of the materials, specifications and processes it takes to build quality into every part. We make every effort to be technically superior, innovative and more responsive to better meet your needs.

We continuously keep up with the latest welding technology and sheet metal fabrication processes, so we can continue to offer high quality and on time delivery at a low cost. We integrate sheet metal fabrication, welding and assembly processes to create high quality products which satisfy all customer requirements; quality, low cost and quick response time.

We have a full range of welding capabilities including micro MIG welding, MIG welding, CO2 welding, and argon welding to name a few.

Our History

A & S McKay was established in 1994 in Birkenhead and is a small family run business which has grown from just two partners to a current workforce of over twenty. This growth is due to the company's reputation for excellent service and quality design and workmanship.

Our capabilities include working with materials such as mild steel, stainless steel, aluminium and other non-ferrous metals. Aluminium castings are a speciality. All our employees are highly skilled (time-served City & Guilds) in the fabrication and welding of all the above materials with equipment on the shop floor i.e. Mig, Tig, MMA and Oxyacetylene.

We can fabricate structures up to 20 tonnes on our premises but on site there would be no limits.

Whatever the design problem we can help. Just give us a ring and discuss it with us.